Closure Based In-Situ Chemical Oxidation

Closure Based In-Situ Chemical Oxidation

Former Gas Station

Location: Confidential Municipality - Southern Alberta

When: 2019-2020

Contaminant of Concern: BTEX, F1, F2, PAH’s

Impacted Media and Volume: 6,630 m3 impacted soil, bedrock and groundwater

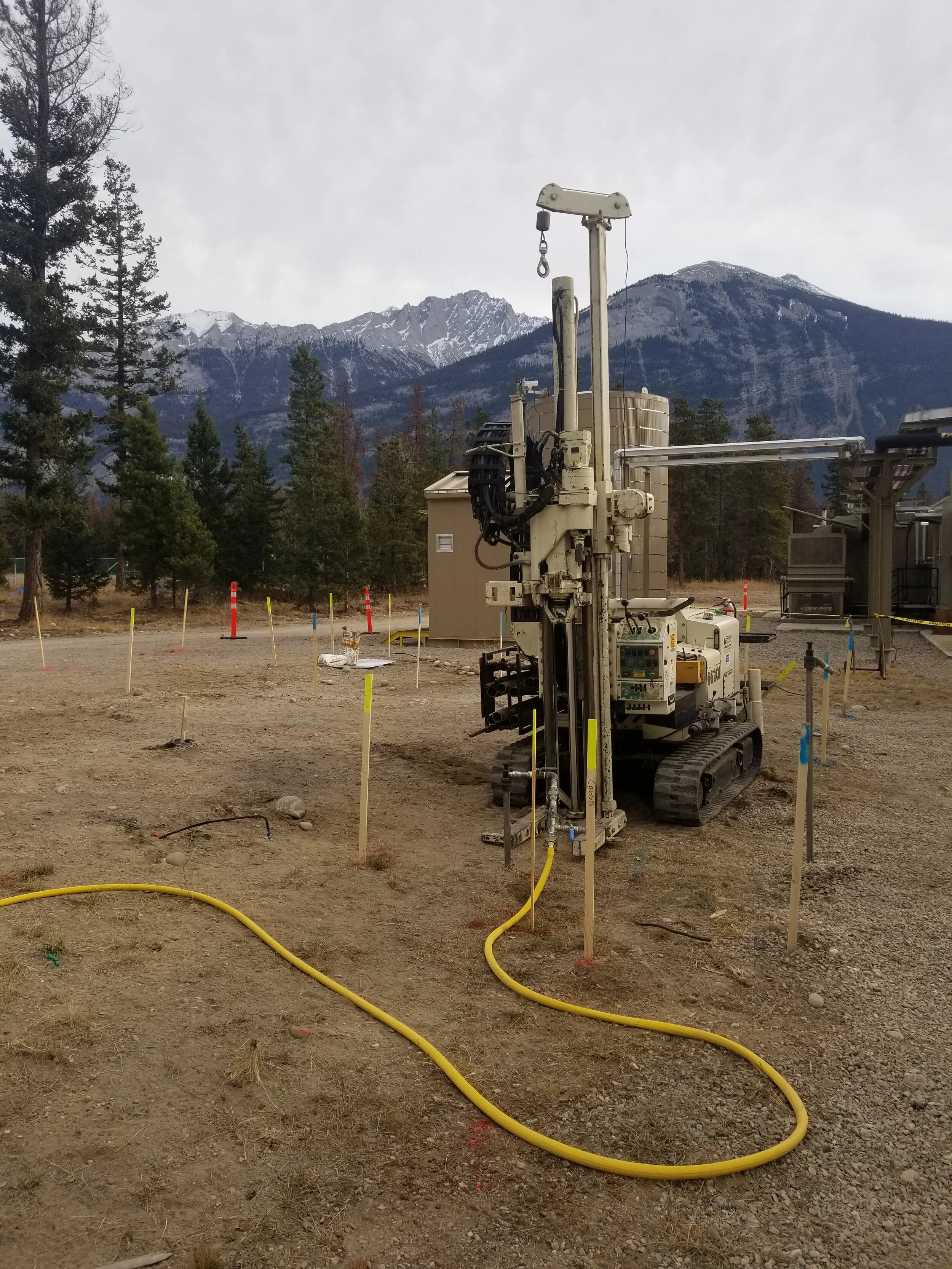

Tasks: In-line dilution system, injection and field monitoring

The Problem

Historical operations in the area had impacted soil and groundwater, extending off-site beneath residential properties. Infrastructure currently in place greatly limited the remedial strategies available. Soil comprised of sands/gravels. Vapour mitigation and management were critical to managing risk to neighbours.

The Approach

A Remediation Train® approach was utilized with a soil vapour extraction (SVE) and air sparge system initially applied followed by an in-situ chemical oxidation (ISCO) program.

The ISCO program is based on 3 meter injection radius of influence to increase contact certainty between the oxidant and the contaminants. Injections were conducted using nested injection wells to target various depth intervals. Injections had to be planned around residential schedules and incorporate “children playing” in backyards.

Over 45 days, injected 1.6 million litres of blended 10% EHP (enhanced hydrogen peroxide) oxidant. Blending is site specific following TRIUM’s ChemOx® process, with blend volumes of >35,000 L per day being achieved.

The Results

Confirmatory groundwater samples following injections met applicable guidelines

SVE system effective to manage and remove vapour risks

Very short timeframe of treatment

Process recognized as “industry leading” by experienced consultants

No negative effect to community or stakeholders