Risk Based In-Situ Chemical Oxidation

Risk Based In-Situ Chemical Oxidation

Pipeline Release at Oil and Gas Site

Location: Wellsite - Central Alberta

When: 2017 - present

Contaminant of Concern: BTEX, F1, F2, PAH

Impacted Media and Volume: 2,000 m3 impacted soil and groundwater

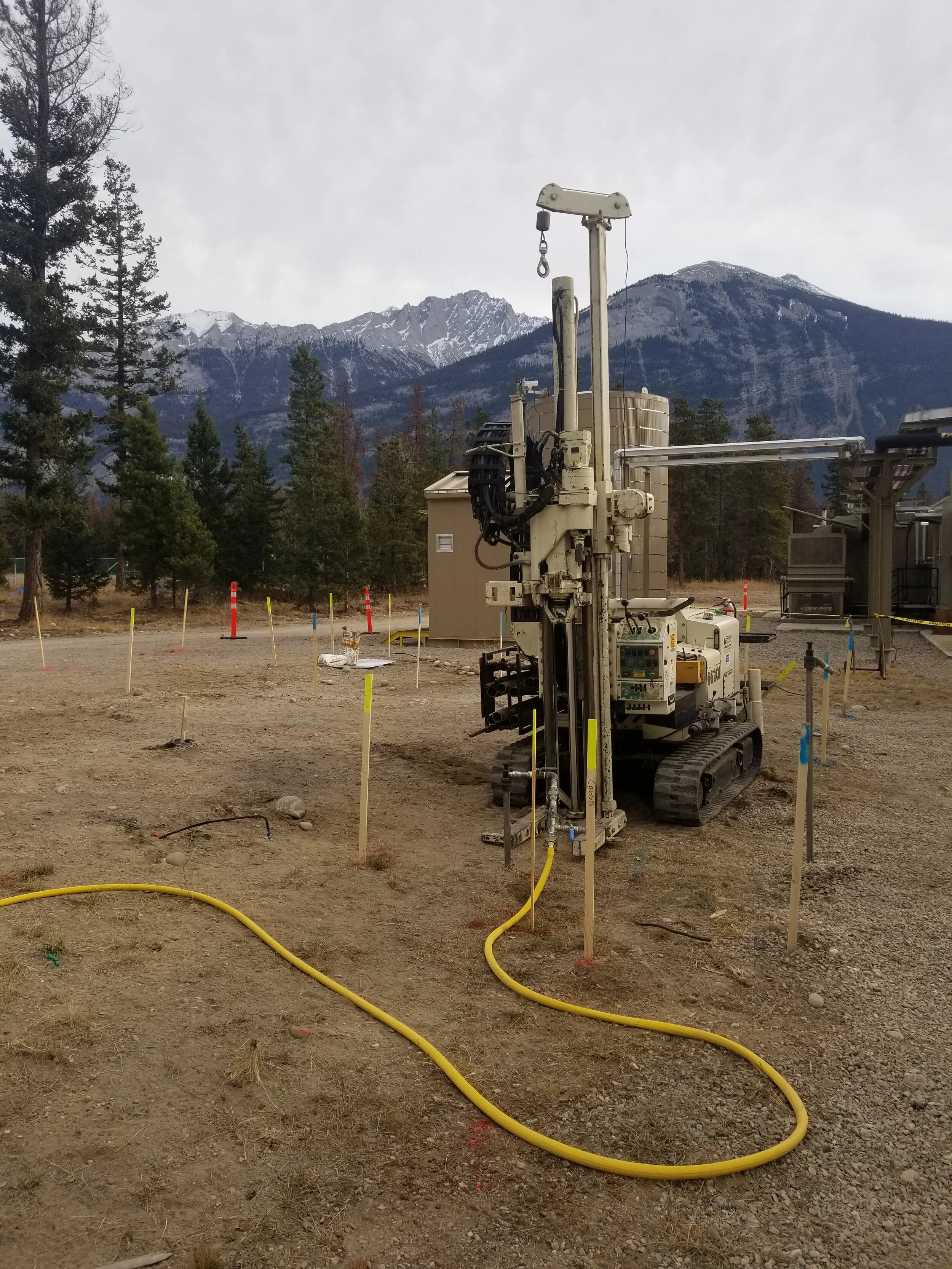

Tasks: Remediation Program Design, Injection Well Installation, Permeable Reaction Trench Design and Construction, Blending, and Field applications

The Problem

Release from a pipeline on an active multi-well pad. Site is a cut and fill with artesian wells on-site on the fill side resulting in limited remediation timeframes. Soil and groundwater impacts to a depth of 4 meters.

The Approach

Staged/Risk based in-situ chemical oxidation (ISCO) program based on 3 meter injection radius of influence. Permeable reaction trenches installed at the source area to allow for groundwater extraction and circulation of oxidant within the trenches. Establish health and safety protocol and site logistics for handling oxidizer.

Installed 52 injection wells and designed/ constructed 5 permeable reaction trenches. Injected/ circulated a total of 17,500 litres of blended 12% EHP (enhanced hydrogen peroxide) oxidant. Blending is site specific following TRIUM’s ChemOx® process. Injections and trench circulations were limited to months with a frost cap to hold pressure/ volume during injections.

The Results

Plume area is well defined based on previous investigations

Plume has been reducing in size

Source area concentrations reducing

Approximately 90% reduction in PHC and PAH concentrations since project commencement