Risk Based In-Situ Chemical Oxidation

Risk Based In-Situ Chemical Oxidation

Pipeline Release

Location: Pipeline release, Central, Alberta

When: 2018-2019

Contaminant of Concern: BTEX, F1, and F2

Impacted Media and Volume: 200 m3 impacted soil and groundwater

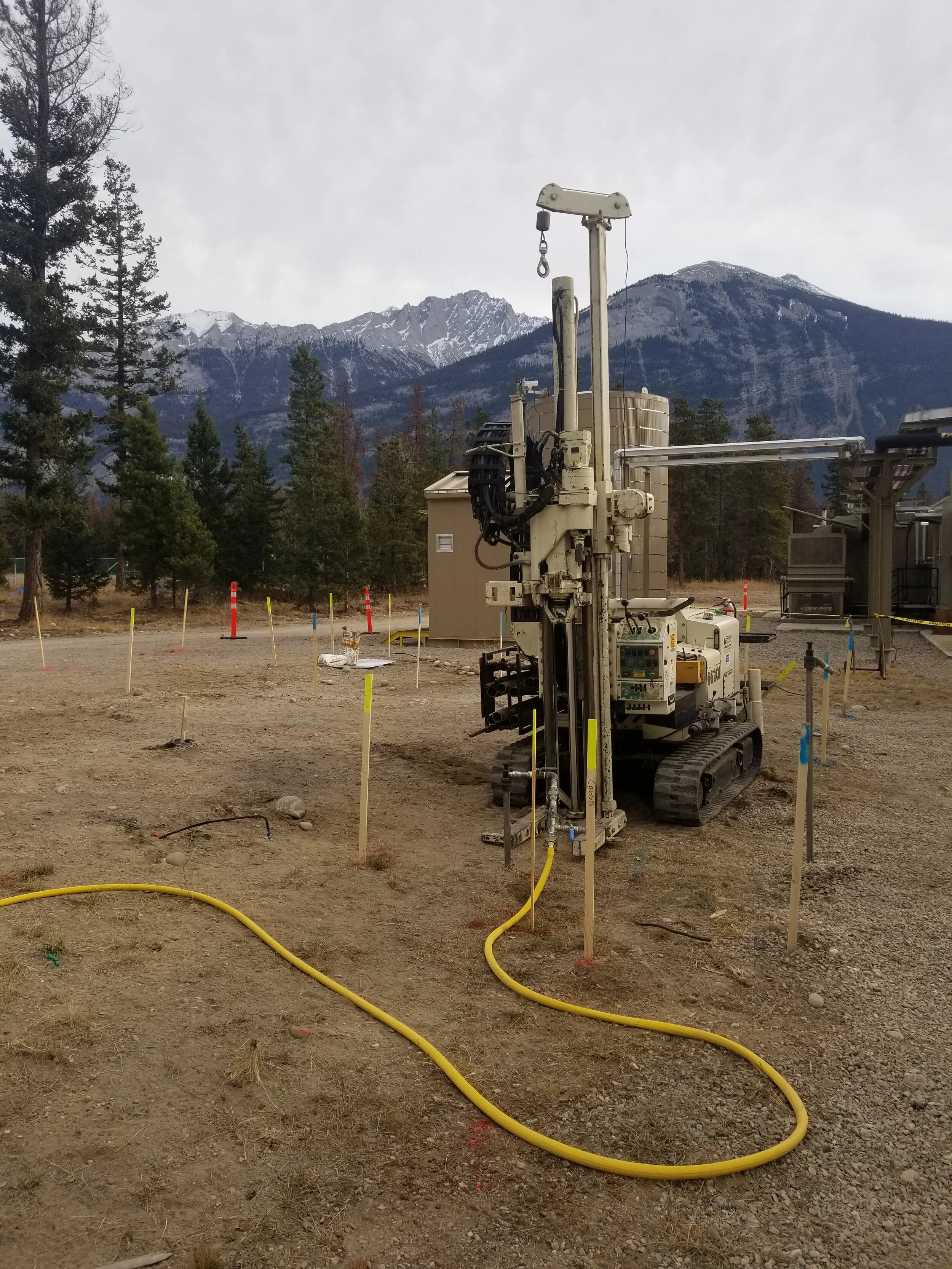

Tasks: Remediation Program Design, Injection Well Installation, Blending, Multi-oxidant approach, and Field applications

The Problem

Pipeline release was being treated using a multi-phase extraction system for non-aqueous phase liquids (NAPL). Residual contamination was unable to be treated using the current system. Lithology at the site comprised of clay with sand lenses as preferential pathways. Petroleum hydrocarbon impacts from 4 to 6 meters below ground surface.

The Approach

Risk based in-situ chemical oxidation (ISCO) program based on 1.5 to 2.5 meter injection radius of influence. Establish health and safety protocol and site logistics for handling oxidizer.

Installed 12 injection wells and injected 6,500 liters of blended 12% EHP (enhanced hydrogen peroxide) oxidant followed with 3,700 litres of a sodium persulfate 15% blend. Blending is site specific following TRIUM’s ChemOx® process.

The Results

Plume area meets all criteria

Removal of all remaining residual NAPL

Very short timeframe of treatment

Excellent reductions noted with injection distributions exceeding planned performance