Risk Based In-Situ Chemical Oxidation

Risk Based In-Situ Chemical Oxidation

Oil and Gas Spill Site

Location: Wellsite – Fort St. John, British Columbia

When: 2019 - Present

Contaminant of Concern: BTEX, LEPH, HEPH, PAH’s

Impacted Media and Volume: 2,700 m3 impacted soil and groundwater

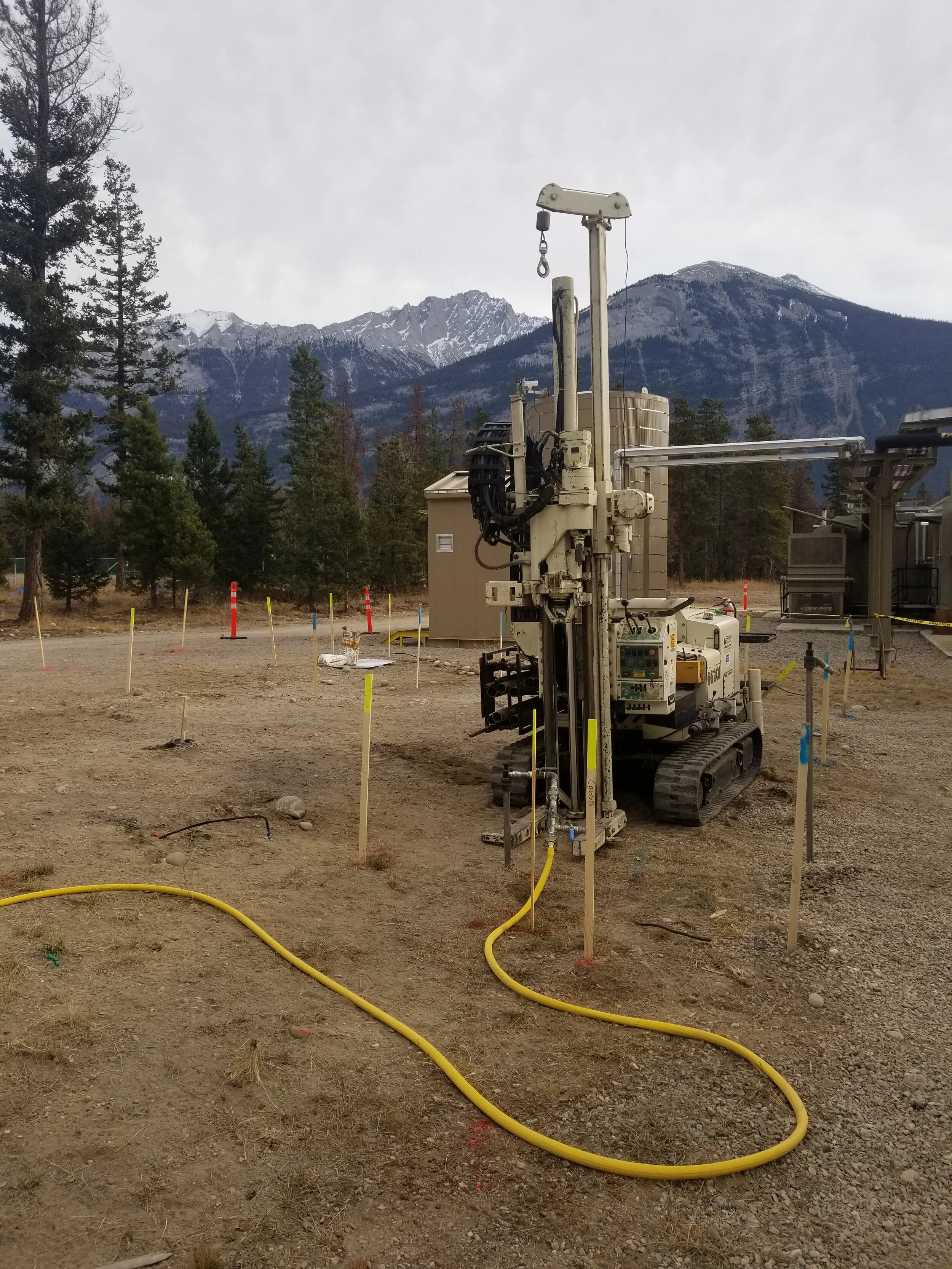

Tasks: Remedial Planning, Detail design, Procurement, Injection Well Installation, Blending and Field applications

The Problem

Former helicopter fuel storage area overlying saturated shallow sands. Fuel (BTEX) contamination within the soil and dissolved in groundwater. Due to shallow groundwater, depths of impacts, and coarse-grained lithology, a winter injection program was developed.

The Approach

Conducted a pilot test at the Site prior to full scale to ensure adequate distribution and determine the most appropriate radius of influence (ROI). Full scale in-situ chemical oxidation (ISCO) program was then conducted based on a 5 meter injection radius of influence. Establish health and safety protocol and site logistics for handling oxidizer.

Installed 42 injection wells and injected 60,000 litres of blended 15% EHP (enhanced hydrogen peroxide) oxidant. Blending is site specific following TRIUM’s ChemOx® process.

The Results

Significant reduction in non-aqueous phase liquids (NAPL) in the groundwater

Significant reduction of overall plume size

Very short timeframe of treatment

Highly cost effective compared to traditional remedial options

Excellent reductions noted with injection distributions exceeding planned performance