Closure Based In-Situ Chemical Oxidation

Closure Based In-Situ Chemical Oxidation

Operational Power Generation Plant

Location: Confidential Municipality - Northwestern Alberta

When: 2018

Contaminant of Concern: F2 and vinyl chloride

Impacted Media and Volume: 300 m3 impacted soil

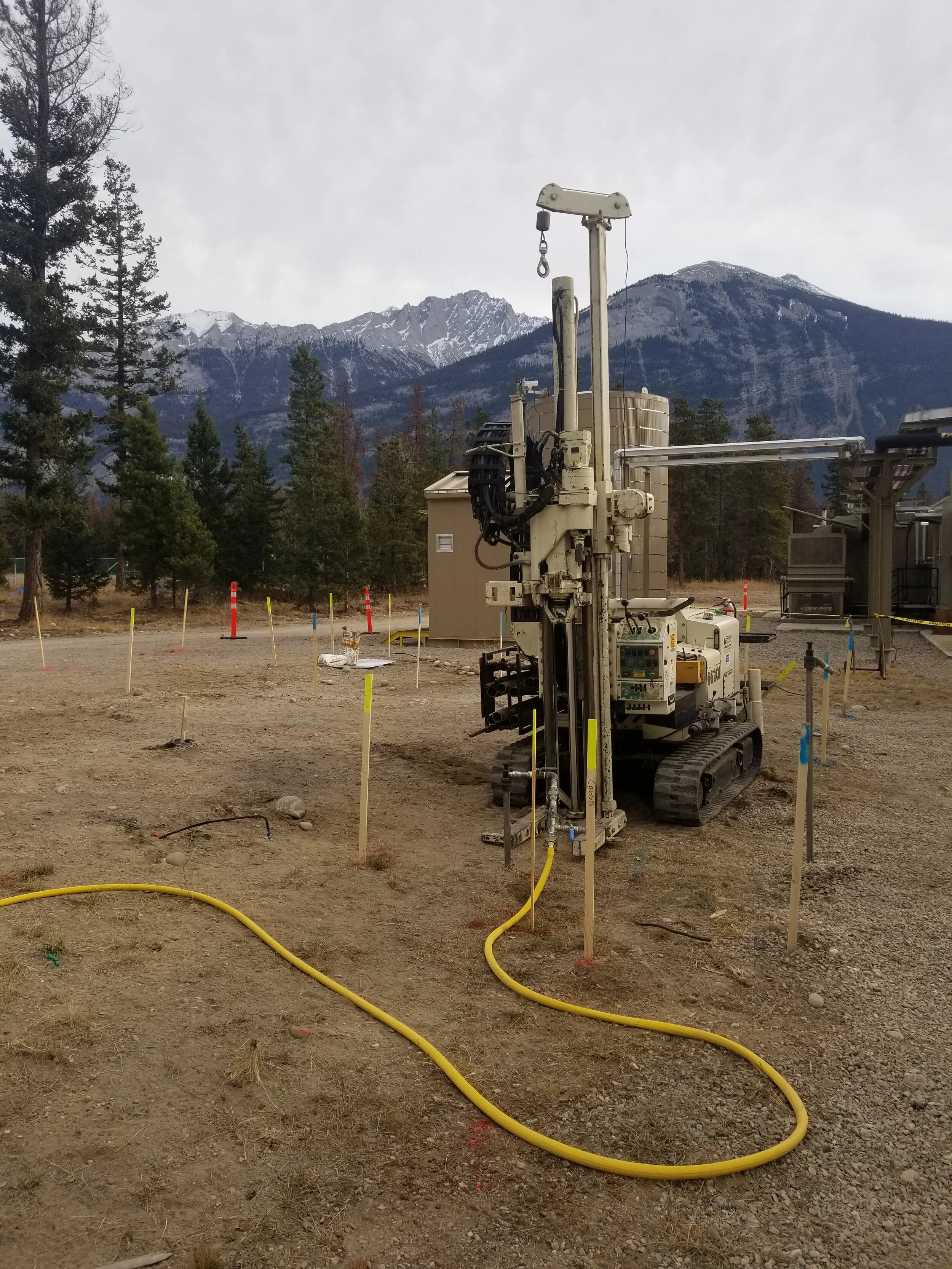

Tasks: In-line dilution system, injection and field monitoring

The Problem

Historical operations in the area had impacted the soil. Infrastructure currently in place limiting the remedial strategies available. Soil comprised of sandy loam with little to no moisture. Groundwater was present deeper than the zone of impacts.

The Approach

In-situ chemical oxidation (ISCO) program based on 0.75 meter injection radius of influence to increase contact certainty between the oxidant and the contaminants due to lack of groundwater. Injections were conducted using drive-points to target various depth intervals within each injection point. Due to current operations, the program demanded that injections could not conflict with day-to-day operations of the facility.

Over 5 days, advanced 37 injection points, and injected 32,800 litres of blended 12% EHP (enhanced hydrogen peroxide) oxidant. Blending is site specific following TRIUM’s ChemOx® process.

The Results

Confirmatory soil samples following injections met applicable guidelines

Very short timeframe of treatment

No facility operational shutdowns required